This is a rough log of the design and build of the electric bike. It''s not really a step by step guide but I hope it''s useful.

The design concept for this bicycle was to base the frame on straight lines and repetition of angles with twin top tubes and no downtube. This would free up space for an electric motor and provide a space for the batteries.

I researched bicycle geometries, construction techniques, electric motors, battery technology and electronics. I tried to ride as many different bicycles as I could and measured the ones that rode well. These known bicycle geometries formed a guide around which the bicycle could be designed.

I needed batteries with high energy density and high discharge rates. The best choice of technology was to use lipo (lithium-ion polymer) batteries. I chose to use four Turnigy three series 5,000 mAh packs wire two parallel two series. This gave an output of 22.2 V and a capacity of 10,000 mAh. Batteries and high current wiring was purchased from Hobby King.

At this stage I had a framework of the design constraints around which the frame would be designed. Here is a CAD file of the skeleton of the final geometry. Below is an image of the CAD model.

A mock up of the frame was made out of wood to test the size and riding position.

I found these two web sites very useful when researching bicycle frame building. Bicycle frame building for the rest of us and Frameforum.

I decided to filet braze the frame as opposed to using lugs. I preferred the aesthetic of the fillet braze with the tubes flowing into one another and lugs were not available in the angles I wanted. A propane torch from Cup Alloys was used for the brazing and the setup can be seen in the image below. I used silver for the joints as I found it easier to work with compared with brass.

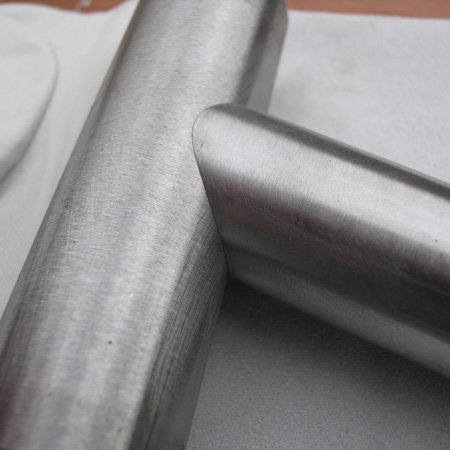

For strong brazed joints a precise fit between the tubes is required. I printed off a paper template, created from the CAD model, and glued it onto the tube to be mitered. I then filed to the line. With practice I could create miters to the accuracy shown below.

At this stage I practice making mock up joints to progress my brazing technique to a point where I was confident enough to start on the bicycle frame. The frame is made almost entirely of Columbus butted steel tubing specifically designed for bicycle frames. All the tubing, dropouts, stays, bosses etc were purchased from Ceeway.